The world’s transition towards renewable energy has put wind power at the center of the clean energy revolution. However, with turbines growing taller and blades reaching more than 100 meters in length, logistics has emerged as one of the industry’s biggest challenges in silence. Hauling these behemoth machines from factories to remote job sites is not just a matter of trucks and cranes—it is as much a military operation in complexity.

Sailing turbine parts is a story of obstacles at every step. Tower sections, even split into segments, are too large and too heavy to pass under bridges or highway interchanges. Rarely does infrastructure need to be taken down temporarily for it to be able to make it through. Blades are the real problem, though. Their vast size makes it nearly impossible to turn sharply, and convoys have to make their way around in a manner through towns or fields. To make this easier, blades are currently being manufactured by some companies in sections, but this brings new difficulties to assembling them on site.

Ports are also being pinched. Once considered doorways to green energy, some ports are now critically choked. Offshore wind farms particularly need colossal space for blade, nacelle, and tower storage. Original units built for lower capacity are being worked around the clock, with every square inch of storage yard taken up during peak production.

When there isn’t space anymore, pieces are set aside at temporary sites miles distant, driving up expenses and working against project timetables. It may take over an hour and an entire crew of man-power to transfer a single blade from one storage bay to another, illustrating just how complex even routine logistics have become.

Route planning is an industry in and of itself. Each project involves examination of potential transport routes, such as on-site observations, computer simulation, and “swept path” analysis to ascertain how the oversize loads will move along bent roads, bridges, and steep grades. Sometimes the chosen route is not the shortest, but the most conservative and disruption-free.

In New Zealand, the builders of a giant wind farm had to rethink their whole plan when equipment grew too large for existing routes. In Australia, contractors transporting 90-meter blades had to navigate narrow rural roads and sensitive environmental zones, illustrating that every project has its own unique set of logistical constraints.

The final phase of the process—shipping turbines to their locations of installation—is generally the toughest. Wind farms are usually located in remote or mountainous regions, far from pavement. Heavy trucks and cranes must inch across soggy ground or muddy hillsides, a procedure that can delay work and damage the environment. Contractors adapt to this situation by laying down hardwood timber mats over the ground to create temporary roads and firm platforms, protecting both land and equipment.

Technology is starting to flip the rules on its head, however. Researchers are experimenting with new materials like thermoplastic resins and 3D-printed components, which have the potential for lighter, more recyclable blades that are easier to tow. Others are developing modular manufacturing, producing blade sections close to the location to cut out long-haul towing altogether.

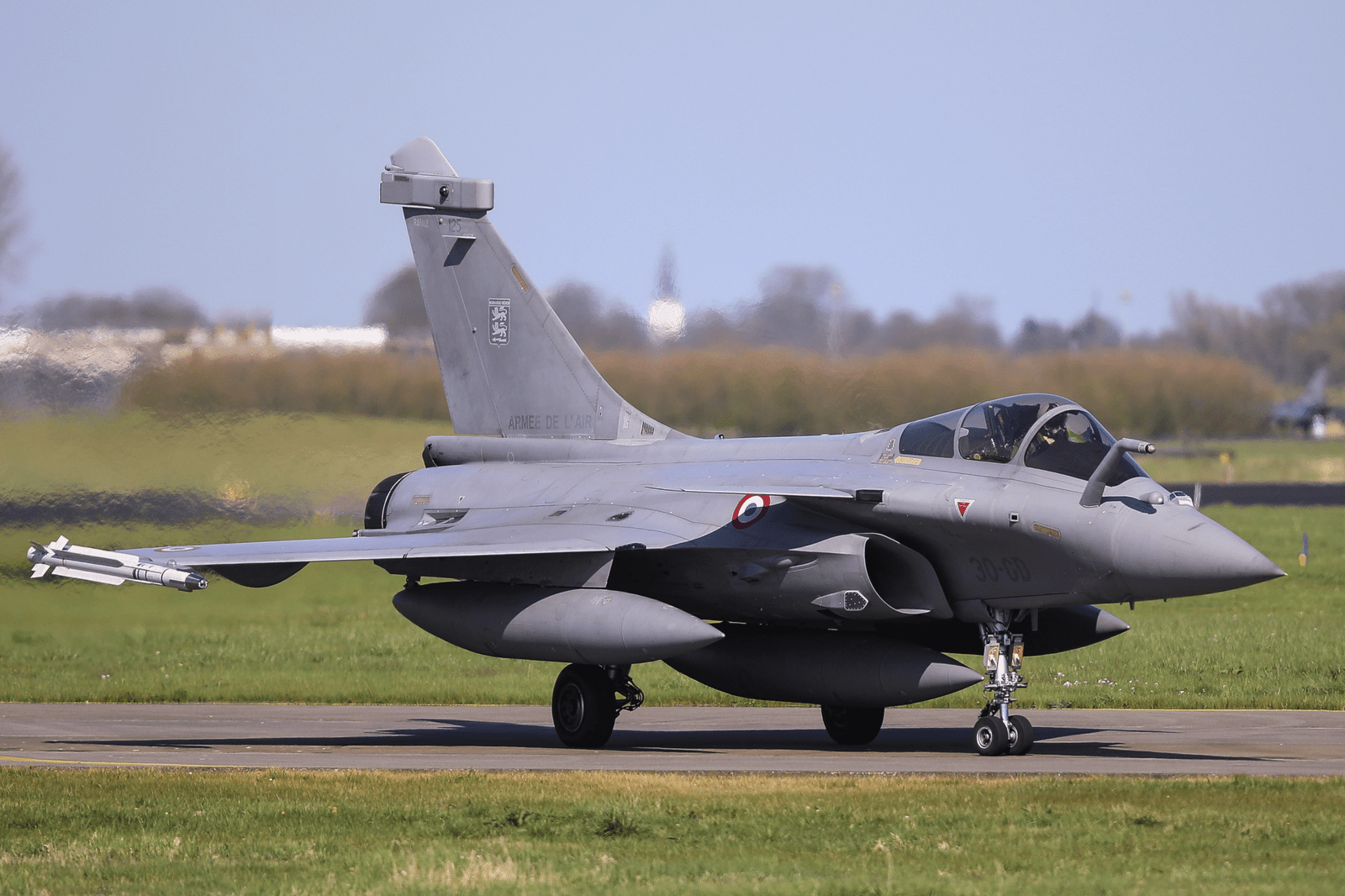

One of the most ambitious ideas is from the aviation sector. A firm is developing a massive cargo plane, the WindRunner, specifically to carry 100-meter-plus turbine blades. With its massive cargo bay and ability to take off and land on primitive airstrips, it could unlock new wind farm sites in remote regions inaccessible to trucks and trains.

Digital technology is also reshaping the logistics pipeline. Real-time tracking software enables firms to see where blades are and in what condition they are traveling, cutting down delays and making sure components arrive in the proper order. Predictive software and more intelligent planning tools enable such bottlenecks to be forecasted, and improved coordination between manufacturers, carriers, and builders keeps projects on time.

Ultimately, solving these logistics problems is just as crucial as designing the turbines themselves. As wind farms move into more hostile terrains and equipment becomes larger, the future of the business will depend on creativity not only in engineering, but in the dirty space of logistics that makes renewable energy possible.